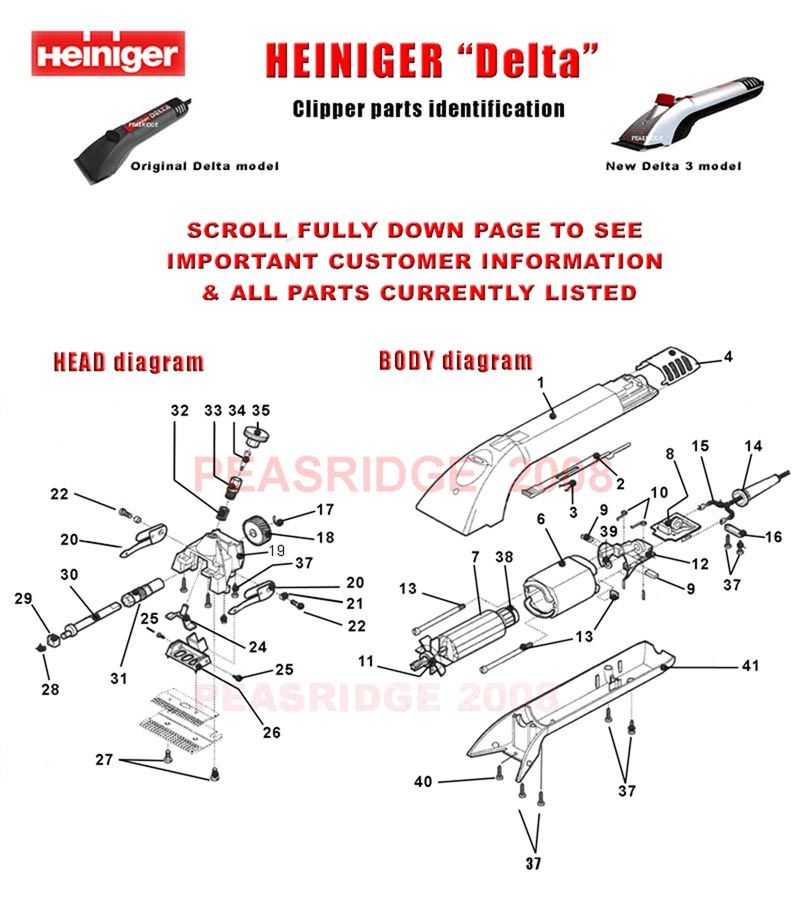

Delta

Customer information

IMPORTANT – CUSTOMERS INFORMATION

This page is under constant construction with new parts being added. Please also note any manufacturer’s updates as listed

Always scroll FULLY down the page to see both updates and current parts listed

Some pages may only show a limited number of parts – you will need to CLICK “View All” (See the top of the page above the diagram or at the bottom of each page)

If you require further advice please contact us.

E-mail:

sales@showtime-supplies.co.uk

Telephone:

UK Mainland: 01759 368 588

Overseas: +44 1759 368 588

PLEASE NOTE

Telephone lines are open from (UK time: ) 1030 to 1230 hours and from 1430 until 1630 hours Monday to Friday. Our offices are shut on Saturday, Sunday and all Bank Holidays.

Product items such as ADAPTERS, BATTERIES & CHARGER UNITS are listed under CLIPPER ACCESSORIES

See STORE SELECTIONS on the LHS of your screen

ORDERING PARTS

Please have details relating to make and model of machine, as well as applicable part or diagram identification numbers to hand. Failure to do this may result in errors in the parts ordered/supplied.

TRADE – DISCOUNTS

Trade discounted prices are available on all parts to bona fide trade repair businesses. Please contact us for further information

SHIPPING

We make every effort to ship parts the same day for next day delivery on the UK Mainland

INTERNATIONAL SHIPPING

We ship worldwide daily.

MANUFACTURER’S UPDATES

<b

Certain changes were made to the head of the “Delta” clipper in 2003 to enhance clipping performance.

All new clippers have “3 speed” printed on the clipper air filter in order to easily differentiate between the old models and the improved models.

Changes included:

1. A new tension system

A new tension screw (part item 33) and a new distance screw

(part item 34) allows for more tension to be built up on the blades for better clipping performance.

These two parts can be put into all Delta clippers.

2. A lubricated crank spindle sleeve (part item 31)

It had been noted that many user of this machine fail to correctly lubricate the crank spindle through the lubrication point on the bottom of the clipper head which can lead to premature wear on the crank spindle, and crank spindle sleeve.

A new crank spindle sleeve which is less dependent on lubrication is now used. As this is a slightly larger diameter the aluminium head (part item 19) is also required for any upgrade.

Upgrade kits are available.

Showing all 8 results

-

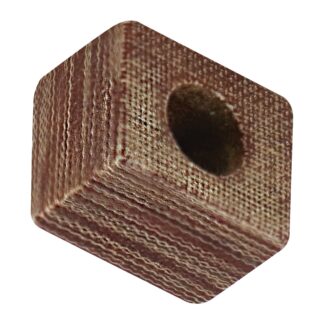

Heiniger Crank Drive Block Canevasit

£5.20 + VAT (£6.24 Inc VAT) Add to cart -

Blade screw

£1.68 + VAT (£2.02 Inc VAT) Add to cart -

Cable Grip

£1.00 + VAT (£1.20 Inc VAT) Add to cart -

Cable Sleeve

£2.72 + VAT (£3.26 Inc VAT) Add to cart -

Carbon brushes

£5.52 + VAT (£6.62 Inc VAT) Add to cart -

Cog

£10.54 + VAT (£12.65 Inc VAT) Read more -

Drive block

£5.20 + VAT (£6.24 Inc VAT) Add to cart -

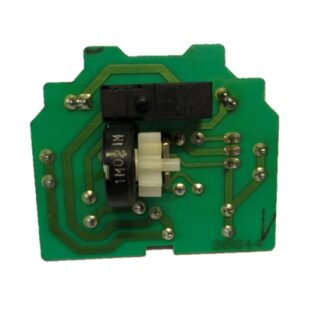

PCB

£48.55 + VAT (£58.26 Inc VAT) Add to cart

Showing all 8 results