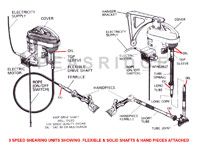

Suspended - mains powered

Drive systems

DRIVE SYSTEMS

There are two “drive” systems to select from – flexi or solid. These are supplied in two connection types – pin or worm.

Flexi drive

Is the connection shaft between the motor unit and the hand piece, normally about 1.8m in length The outer sheath is flexible with the inner mechanics rotating to drive the hand piece. A flexible drive shaft allows a degree of movement by the shearer and is often preferred by those who shear infrequently. Customers should select the connection system – pin or worm as this will affect both the driveshaft and hand piece.

Solid drive

Is the connection shaft between the motor unit and the hand piece, normally about 1.8m in length. The shaft is solid as opposed to being flexible with the inner rotating mechanics driving the hand piece. A solid drive shaft allows little movement by the shearer but is the preferred choice of those who shear frequently. (Contractor gangs). Customers should select the connection system – pin or worm as this will affect both the driveshaft and hand piece. .

Drive connections

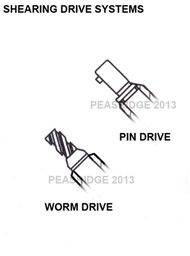

DRIVE CONNECTIONS

When selecting drive connections for either the flexi or solid drive systems customers will need to decide their preference if buying new or if renewing plant (the system adopted for example by any hand piece intended for future use)

Pin drive

This is best described as a “bayonet type fitting (such as used on European light bulb!) It is fitted in the socket using a “push and twist method” Very easy to do. Most shearers do it with the motor running for a faster connection.

Worm or Spline drive

Looks rather like a twisted spline of metal, (metal twisted around to form a “spline” rather like the metal teeth on an clipper armature.) This is fitted in a “straight offer into appliance and push” Some shearers consider it a fraction quicker to set up than the Pin drive system.