Correct fitting

FITTING CUTTER & COMB BLADES to shearing machines heads

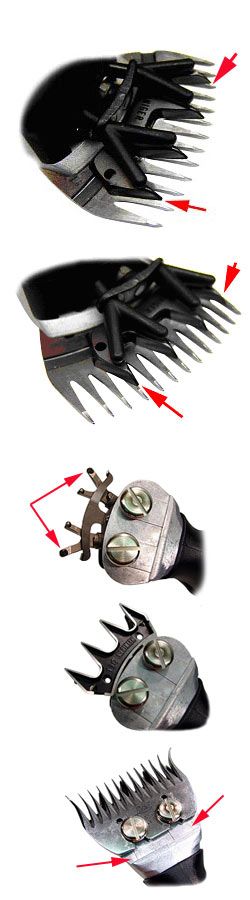

Three common faults seem to catch a lot of people out when fitting cutters & combs unless you have been correctly instructed. The first is not to seat the cutter blade (smaller of the two blades) correctly. Secondly to push the comb blade (larger of the two blades) to far back so that it is tight against the back bar of the shearing machine head. Note the space as shown in the last image – the two red arrows indicate! Thirdly – a failure to observe the importance of the cutter blades teeth not protruding over the ridge of the comb blade teeth.

Naturally before embarking on fitting cutters and combs disconnect the machine from any main electrical power supply!

First, before attempting anything fitting of the blades, first loosen the tension nut, on the shearing machine head to reduce any existing tension. The first blade to be attached to the shearing machine head is the cutter blade. This is the smaller of the two blades and usually it has four teeth. (Machine which use only narrow blades will take a cutter with usually only three teeth.) On most modern shearing machine the cutter is “seated” on two “cones” protruding up from the pressure yoke. (These look like two forked prongs)

Once securely seated you should take the other blade – known as the comb – this is the larger blade with considerably more teeth) and slide it – so that the two slot cut into back of the comb blade – slip under the two large head screws situated on the clipper head base. (These you will have slackened off first!)

Once both blades are in place lightly tighten the two large nuts, enough to hold the comb blade in place. Next rotate the machine until it is the right way up and then gently move the lower comb blade until the upper cutter blade tips are “riding” the crown of the bevel of the comb by the required amount as described in you appliance manual. (Usually 1.5 – 2.0mm) Figures 1 and 2

This is the important bit, which will determine the success or failure of your shearing activity! Get it incorrect and the machine will not clip as it is intended to! Check that both the right and left hand side teeth of the cutter blades to do not over shoot the sides of the comb blade. If either do you need to check the alignment and correct accordingly. Failure to do so may well result in “nicking” the skin of the sheep. In essence it is all very simple – may require a bit of practice – but if over looked – you are doomed!

One last factor, which often catches the “novice” out, is if you forget to take up the slack with the tension nut, when you switch the machine on, blades fly in every direction! As a common sense factor always point the machine away from yourself, other people close by, and not least of all, the animal/s before switching on the power!

Oiling:

As with any form of clipping, one is involved with rapidly moving parts and therefore lubrication – regular lubrication – is essential. A reasonable sized oil can with a long spout and finger lever is ideal. Saturation of oil is not necessary – a few drops along the blades, and squirt a few drops in the various oiling holes as described in your machine manual is adequate but do do it frequently – literally every few minutes. If you are using a traditional handpiece as attached to either a solid or flexible shaft with a suspended motor as opposed to the “motor in the handpiece” type machine remember some of these handpiece need a reservoir of oil held within the handpiece casing. Always check the oil level before starting shearing and top up accordingly. Consult the instruction manual.

REMEMBER!

Shearing cutters and combs – just like horse or cattle blades – go blunt without warning. If you intend shearing all your flock the same day, make sure you have enough blades. Ensure you are not brought to an abrupt halt due to running out of sharp blades! If you have say: 10 sheep – a good ratios might be: 1 comb/3 cutters. 20-30 sheep: 2 combs/ 5 cutters. 50/100 sheep: 5 combs/12-15 cutters. 100-250 sheep: 10combs/25-30 cutters. Much relating to how the sheep shear to be honest will depend on the conditions of the day. Conditions vary from farm to farm, area or region and of course the weather can be a big influence. You may only use a proportion of the suggested number of blades, but one thing for sure it is a lot easier to have enough blades as opposed to rounding all your “woollies” up again and starting where you left off!

No products were found matching your selection.